When browsing our spec sheets or catalogues, you may have seen an IP rating (such as IP66) or an IK rating (like IK08) listed alongside a luminaire as a selling point or a feature. You may know that the IP rating somehow relates to waterproofing, and the IK rating relates to impact resistance, but do you know what the individual codes actually mean? We’ll try to explain it using simple terms in this article.

Both Ingress Protection (IP) & Impact Resistance (IK) codes relate to standards prepared and published by the International Electrotechnical Commission (IEC). These standards aim to provide end users and consumers with greater clarity regarding the protection electrical devices offer against dust or water intrusion and external impacts. Devices need to be tested by an accredited laboratory before claiming compliance.

IP Rating – Ingress Protection

We’ll start with the IP rating – defined in International Standard IEC 60529, the IP rating classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion from foreign objects, dust and water. All electrical devices have an IP rating, even the device you’re reading this article on.

Did you know IP Ratings can (or could) contain up to 5 digits? Here’s a breakdown of what each digit represents:

| Code Letters: | First Digit: (Solid Particle Protection) | Second Digit: (Liquid Ingress Protection) | Third Digit: (Mechanical Impact Resistance) | Additional Letter: (Other Protections) | Supplementary Letter: (Other Protections) |

|---|---|---|---|---|---|

| IP (Ingress Protection) | Single Numeral: 0-6 or letter X | Single Numeral: 0-9 or letter X | Single Numeral | Single Letter | Single Letter |

| Mandatory | Mandatory | Mandatory | No Longer Used (Replaced by IK Rating) | Optional | Optional |

An IP rating should always include the letters ‘IP’ followed by at least two digits – for example IP68. The first digit covers protection from solids, while the second digit covers protection from liquids. A simple rule to remember: the higher the numbers are, the more protection offered.

Previously, a third digit was used to represent mechanical impact resistance. This third digit has now been replaced by the IK rating and is no longer used. The fourth and fifth digit are optional, and indicate protection against certain body parts or equipment, and protection of equipment for specific applications, such as oil resistance or a high-voltage apparatus.

The First Digit

In greater detail, the first digit indicates the level of protection the enclosure / device provides against access to hazardous or internal parts (e.g. electrical conductors or moving parts) and the ingress of solid foreign objects such as a body part or even dust.

| Level | Protection Against: | Notes: |

|---|---|---|

| X | No data available to specify a protection rating | |

| 0 | No protection | |

| 1 | Foreign Objects > 50mm diameter | Example: back of a human hand |

| 2 | Foreign Objects > 12.5mm diameter (not greater than 80mm in length) | Example: a human finger |

| 3 | Foreign Objects > 2.5mm diameter | Example: tools, thick wires |

| 4 | Foreign Objects > 1mm diameter | Example: wires, slender screws |

| 5 | Dust Protected | |

| 6 | Dust Tight | Vacuum test of up to 8 hours required |

The Second Digit

The second digit indicates the level of protection that the enclosure provides against harmful ingress of water (side note: the ratings for water ingress are not cumulative beyond IPX6 – i.e. a device compliant to IPX7 is not necessarily compliant with IPX6. A device compliant to both is indicated by listing both codes separated by a slash – ie IPX6/IPX7. Standard IP codes should never include a hyphen, like IP6-9 – this is an invalid code.

| Level | Protection Against: | Test Duration: |

|---|---|---|

| X | – | |

| 0 | None | |

| 1 | Condensation / dripping water | 10 minutes total |

| 2 | Dripping water when tilted at 15° | 10 minutes total |

| 3 | Spraying water | 5-10 minutes |

| 4 | Splashing of water | 10 minutes |

| 5 | Water jets | At least 3 minutes |

| 6 | Powerful water jets | At least 3 minutes |

| 6K | Powerful water jets with increased pressure | At least 3 minutes |

| 7 | Immersion, up to 1 meter depth | 30 minutes |

| 8 | Immersion, 1 meter or more depth | Greater than 30 minutes* |

| 9K | Powerful high-temperature water jets | 2-3 minutes |

*IPX8 test duration and depth specified by the manufacturer. It is generally expected to be greater than the requirements for IPX7.

Using what we now know, let’s examine the Cree Lighting Syrius (below left) which offers an ingress protection rating of IP66. The first ‘6’ indicates it offers complete protection against dust, while the second ‘6’ signals it will endure water projected by powerful jets against it to no harmful effect. A rating of IP65/66 is typical for exterior luminaires, which are subject to environmental conditions like dust, pollution, humidity and rain.

To achieve this rating, the Syrius needs to be tested to ensure compliance. The Standard dictates the parameters that need to be met for each category. In the case of the Syrius, to achieve the ‘dust-tight’ rating (indicated by the first ‘6’ in ‘IP66’), a vacuum test of up to 8 hours must be applied. To earn the second ‘6’ (withstand powerful water jets), the Syrius’ enclosure needs to be capable of withstanding a certain amount of water (100 litres per minute) sprayed using a certain nozzle (12.5mm) for a specific length of time (at least 3 minutes) at a certain pressure (100 kPA) from a certain distance (3m).

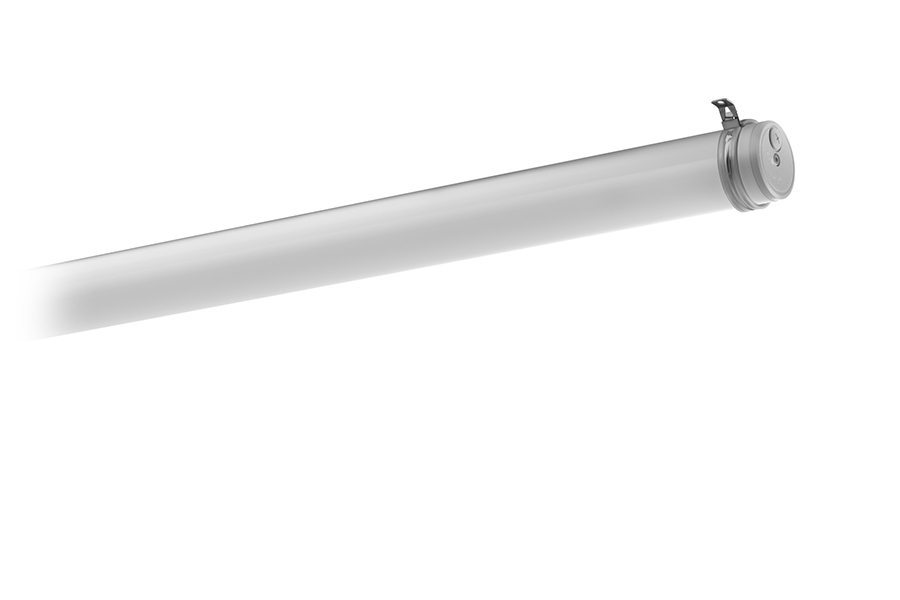

Another interesting example is the PRACHT Tubis (below right) which offers an ingress protection rating of both IP67 & IP69K (Remember, IP ratings beyond IPX6 are not cumulative – holding two ratings means the Tubis is compliant with both IP67 and IP69K).

The letter K indicates a rating to withstand high-pressure, high-temperature washing and was originally developed for road vehicles (especially those that require regular intensive cleaning like dump trucks or concrete mixers) but has also been used in other areas, such as industrial lighting. Such a rating allows the PRACHT Tubis to be considered for use in agricultural, industrial or manufacturing applications, which may require equipment be subject to regular and intensive cleaning procedures.

The Cree Syrius (left) offers an Ingress Protection rating of IP66, while the PRACHT Tubis (right) features both IP67 & IP69K ratings.

IK Rating – Impact Resistance

The IK rating is defined in IEC 62262 (2002) and classifies the degree of protection offered by electronic equipment devices/enclosures against external mechanical impacts, like accidental collisions or acts of vandalism.

The testing parameters to achieve each level typically involve the device withstanding strikes from objects of a specific shape and weight, being dropped from increasing heights using different methods (such as free falling or pendulum swinging – see table below).

| Level | Impact Energy: (Joule) | Weight Of Object Used: | Free Fall Height: |

|---|---|---|---|

| IK00 | No protection | N/A | N/A |

| IK01 | 0.14 | 0.2kg | N/A |

| IK02 | 0.2 | 0.2kg | N/A |

| IK03 | 0.35 | 0.2kg | N/A |

| IK04 | 0.5 | 0.2kg | N/A |

| IK05 | 0.7 | 0.2kg | N/A |

| IK06 | 1 | 0.5kg | N/A |

| IK07 | 2 | 0.5kg | 0.40m |

| IK08 | 5 | 1.7kg | 0.30m |

| IK09 | 10 | 5kg | 0.20m |

| IK10 | 20 | 5kg | 0.40m |

Let’s look at the PRACHT Katla BL (below left) for example, which features an impact resistance rating of IK08. This means the Katla BL has been tested to endure a 5-joule strike from a free falling 1.7kg steel object (with a 25mm radius) from a height of 300mm. It would also need to withstand a strike from the same object using the pendulum (swinging) method.

Like the IP rating, the higher the IK code digits are, the more protection offered. Occasionally, manufacturers will go above and beyond the requirements of the Standard. For example, the PRACHT Troja G2 (below right) can withstand impacts of up to 100 joules – five times the amount required to achieve an IK10 rating.

The PRACHT Katla BL (left) offers an Impact Resistance rating of IK08, while the PRACHT Troja G2 (right) is rated IK10, but can withstand much more impact.

As mentioned above, before the advent of the IK code, a third numeral was occasionally added to the IP code to indicate the level of impact protection – ie IP669 or IP66(9). This is no longer accepted.

Further information regarding each classification’s testing parameters is readily available online.

Disclaimer:

The information provided in this document has been provided in good faith by Advanced Lighting Technologies (ADLT). It is intended as a general guide only. ADLT welcomes any comments or feedback on this subject through our contact page.

Professional advice should be sought before relying on the information provided. ADLT does not warrant accuracy of the information and disclaims any legal responsibility for any loss or damage which may be suffered directly or indirectly, by relying upon the information provided.

References:

Some modifications and additions have been made to text taken from the below pages. Pages retrieved 21/12/2021 & 22/12/2021.

– https://en.wikipedia.org/wiki/IP_Code

– https://en.wikipedia.org/wiki/EN_62262

– https://en.wikipedia.org/wiki/International_Electrotechnical_Commission

SPECIALISTS IN LED LIGHTING SOLUTIONS

Advanced Lighting Technologies (ADLT) has been a leader in the lighting market for over 25 years. With an established presence in Australia, New Zealand and Southeast Asia, we specialise in architectural, commercial and industrial lighting solutions designed for dozens of industries. Whatever the application, whatever the budget – we’ll have a solution that fits your needs.

Contact us for more information on an energy-efficient LED lighting solution today.